BAR GRINDING

CAPABILITIES

PRECISION GRINDING

LONG BAR & TUBE

Today’s market requires the utilization of modern, versatile precision grinding equipment capable of producing the highest quality product at the lowest possible cost. For more than 40 years, BPC has been providing the industry with precision ground bar and tube.

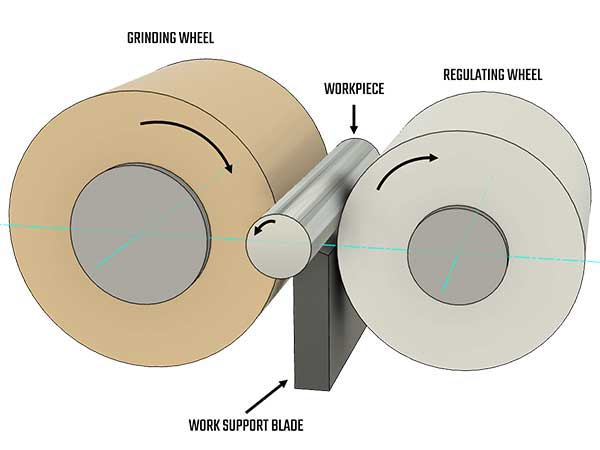

Centerless grinding is a precision machining process used to grind the outer surface of steel bars without the need for a central axis or fixture to hold the workpiece in place. A steel bar is held between two rotating grinding wheels, with one fixed (grinding wheel) and the other movable (regulating wheel) allowing the bar to be ground along its outer diameter. The final result is a steel bar with a smooth, polished surface and a consistent diameter along its entire length. The outer diameter of the bar can be precisely controlled, making this method ideal for applications where the bars need to be uniform in size and shape.

BENEFITS OF CENTERLESS GROUND BARS:

- High Precision and Tolerance

- Consistency and Uniformity

- Cost Effective for High Volume Production

- Improved Surface Quality

- Minimal Material Waste

APPLICATIONS OF CENTERLESS GROUND BARS:

- Automotive

- Aerospace

- Medical Devices

- Manufacturing

- Industrial Components

| Process | Warren, Michigan | Newton Falls, Ohio | Wickliffe, Ohio | Chicago Hts., Illinois |

|---|---|---|---|---|

| CENTERLESS GRINDING | ||||

| MIN/MAX DIAMETER | – | 0.500″ – 2.500″ | – | – |

| MIN/MAX LENGTH | – | 18″ – 26′ | – | – |

| Click Here to DOWNLOAD a Full Capability Summary by Location | ||||